|

NTD Hopper Lifting Charging MachineThis machine is mainly used for conveying and feeding solid materials in the pharmaceutical industry. It can be used in conjunction with mixing machines, tablet presses, capsule filling machines, and other equipment. It is widely used in industries such as pharmaceuticals, chemicals, and food.

收藏

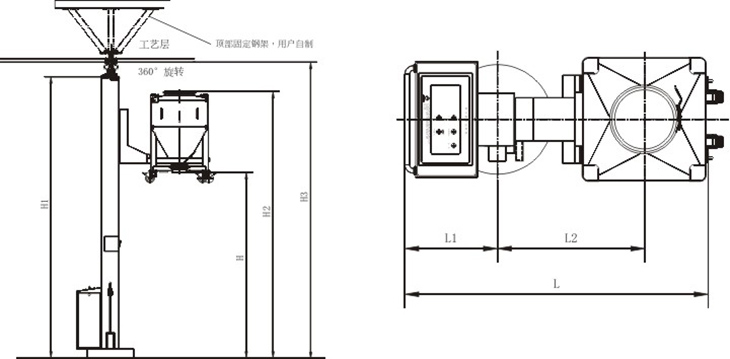

Purpose This machine is mainly used for conveying and feeding solid materials in the pharmaceutical industry. It can be used in conjunction with mixing machines, tablet presses, capsule filling machines, and other equipment. It is widely used in industries such as pharmaceuticals, chemicals, and food. Principle The machine is mainly composed of chassis, pillars, lifting system and other components. When working, first push the hopper containing materials into the fork frame of the hopper elevator, then activate the lifting button, and the hopper will perform lifting motion. After the hopper is in place, rotate the chassis to tightly connect with the feeding equipment, open the discharge butterfly valve, and transfer the materials to the next process in a sealed manner. Characteristic This machine is a new model developed by our company that has widely absorbed and digested advanced foreign technology, and combined with national conditions. Reasonable structure, stable performance, easy operation, no dead corners or exposed screws on the entire machine. This machine is easy to clean, effectively controls dust and cross contamination, optimizes production processes, and fully complies with GMP requirements for drug production. purpose This machine is mainly used for conveying and feeding solid materials in the pharmaceutical industry. It can be used in conjunction with mixing machines, tablet presses, capsule filling machines, and other equipment. It is widely used in industries such as pharmaceuticals, chemicals, and food. principle The machine is mainly composed of chassis, pillars, lifting system and other components. When working, first push the hopper containing materials into the fork frame of the hopper elevator, then activate the lifting button, and the hopper will perform lifting motion. After the hopper is in place, rotate the chassis to tightly connect with the feeding equipment, open the discharge butterfly valve, and transfer the materials to the next process in a sealed manner. characteristic This machine is a new model developed by our company that has widely absorbed and digested advanced foreign technology, and combined with national conditions. Reasonable structure, stable performance, easy operation, no dead corners or exposed screws on the entire machine. This machine is easy to clean, effectively controls dust and cross contamination, optimizes production processes, and fully complies with GMP requirements for drug production. |