Features

1 .Fluid bed to achieve fast heat transmission of medium.

2.Seal negative pressure operation, there is no dust.

3. Because of using anti-static material as filter, it is safe in operation;

4. The equipment has no dead corner so it is easy to clean fully and there is no cross pollution;

5.It is conformity with the requirements of GMP.

Applications

The machine is main used for drying powder or granules from pharmaceutical,foodstuff, chemical and so on industries.

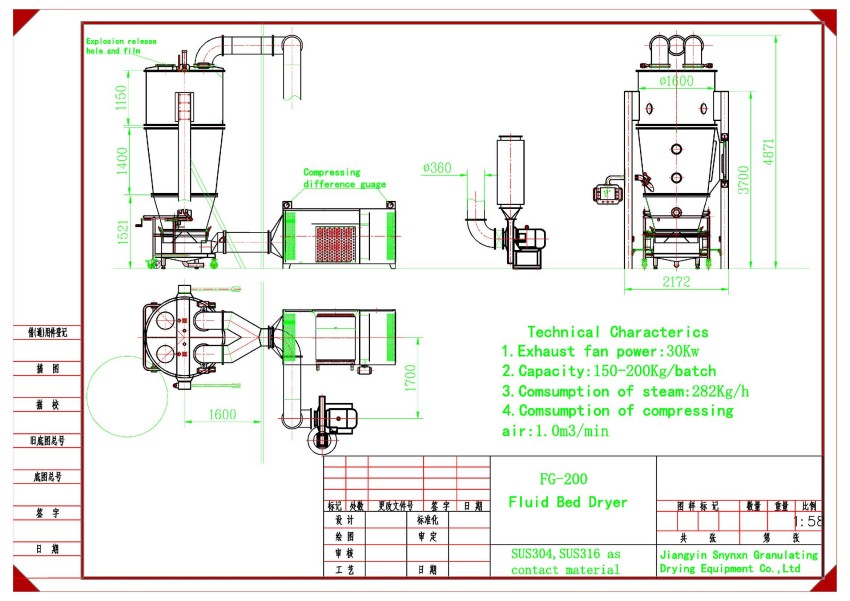

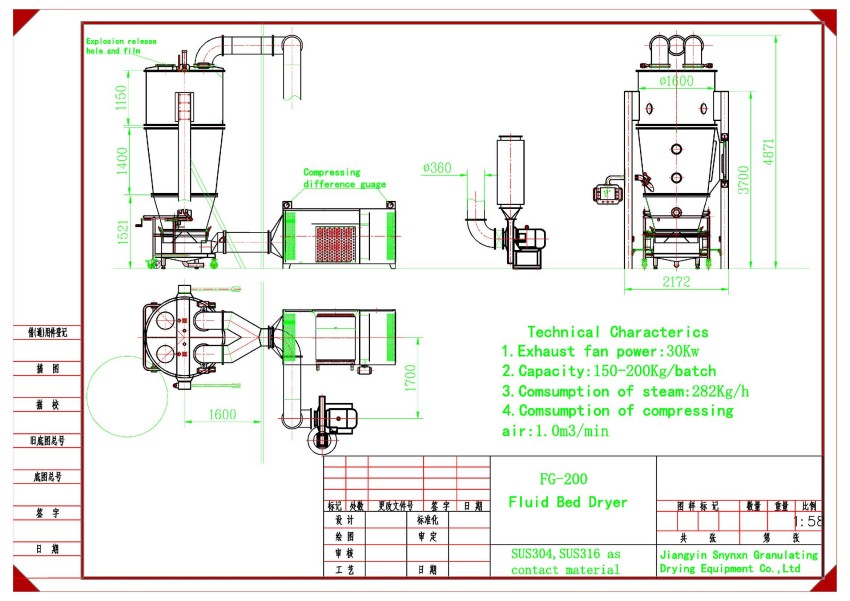

Technical Parameter

| Type | 3 | 5 | 30 | 60 | 120 | 200 | 300 | 500 | 1000 |

| Item | unit |

| Container of raw material | diameter | mm | 300 | 400 | 700 | 1000 | 1200 | 1400 | 1600 | 1800 | 2200 |

| volume | L | 12 | 22 | 100 | 220 | 420 | 670 | 1000 | 1500 | 2500 |

| Capacity | min | kg/batch | 1.5 | 4 | 15 | 30 | 80 | 100 | 150 | 250 | 500 |

| Production capacity | max | kg/batch | 4 | 6 | 36 | 72 | 140 | 240 | 360 | 600 | 1100 |

| Consumption of steam | kg/h | 12 | 23 | 70 | 140 | 211 | 282 | 366 | 465 | 800 |

| Amount of compressed air | m3/min | 0.3 | 0.3 | 0.3 | 0.6 | 0.6 | 0.9 | 0.9 | 0.9 | 1.5 |

| Power of fan | kw | 2.2 | 4 | 5.5 | 11 | 18.5 | 22 | 30 | 45 | 75 |

| Temperature | ℃ | (Adjustable from ambient to 120) |

| Yield | % | >99 |

| Option time | min | 15〜30(depends on material) |

| Content at final term. | % | -0.2( depends on material) |

| Noise | dB | ≤75 |

| Height of main machine | mm | 2100 | 2300 | 2500 | 3000 | 3300 | 3800 | 4000 | 4800 | 6200 |